What is a 3D Laser Scanning Survey?

posted 24th June 2024

3D laser scanning can actually be dated back to the 1960s. Thanks to advancements in technology, it has evolved into a powerful technology, playing a vital role in surveying construction sites. It is highly accurate, creating a detailed three dimensional representation of the structure or land.

What is 3D Laser Scanning?

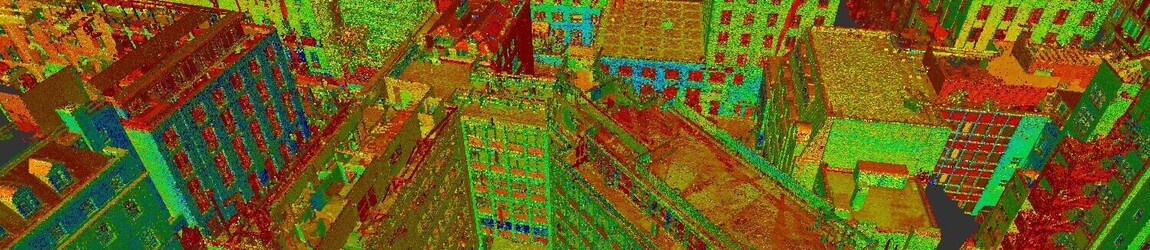

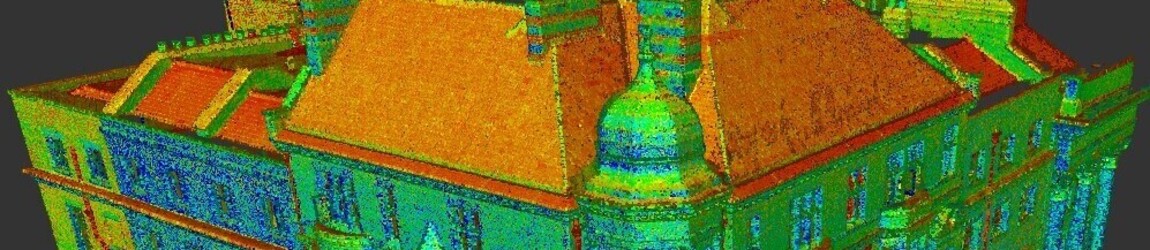

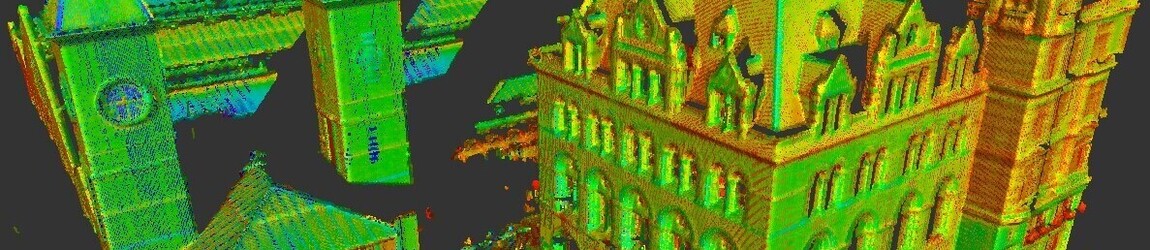

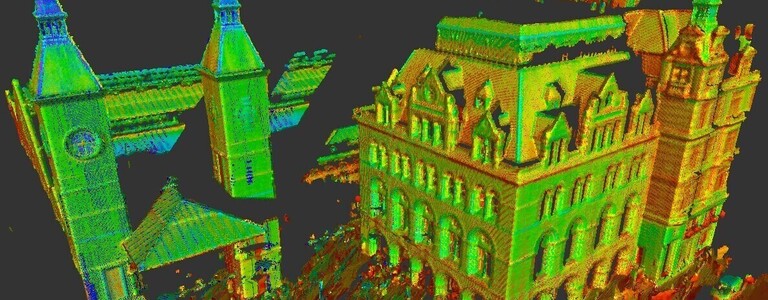

3D laser scanning is process of examining a building or piece of land, gathering vital information to reconstruct the shape or appearance. This procedure transforms the object being scanned into a 3D model. It is helpful as a foundation for the build project, helping to analyse the land and identify if the build is viable.

There isn't only one tool or technique used in 3D laser scanning. There are multiple methods that generate a digital representation of the land or building.

How Does it Work?

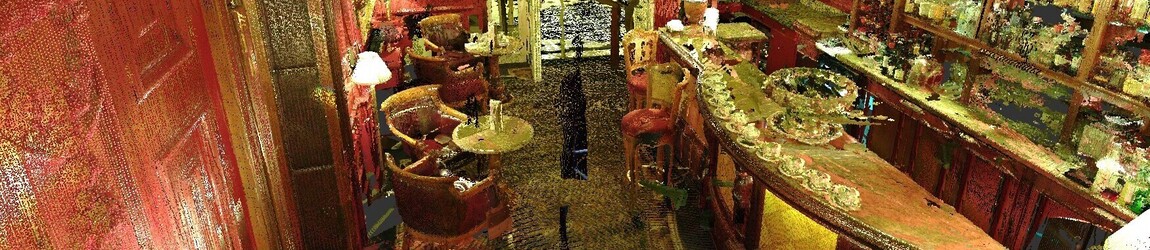

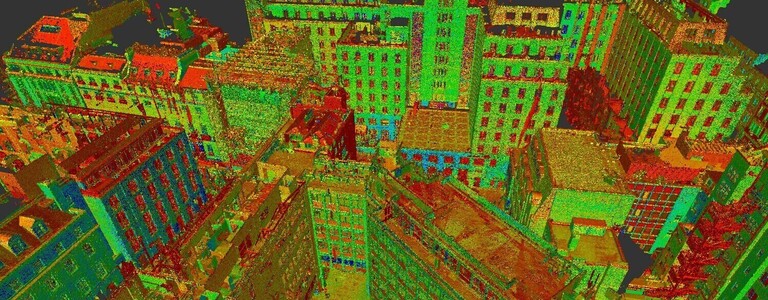

A laser scanner uses high speed pulses of light that bounce off structures or objects, returning to the scanners sensor. Some 3D laser scanners can capture millions of data points per second. The time lapse between the send and receive pulse determine the distance between the item and the scanner, with outstanding accuracy.

3D laser scanners are not only used in construction, it is also used in a variety of other applications, including industrial manufacturing to enhance quality control and equipment maintenance. Preserving historical sites by documenting current condition and artefacts in high detail, along with forensics. In forensics, they can use the 3D scanner to provide accurate and detailed information to assist with investigations and in court.

What Surveys Use 3D Laser Scanners?

These scanners have the ability to capture millions of data points and are used in building surveys including producing floor plans, elevations, cross sections, and drawings. The technology enables the surveyor to produce realistic photographic representations and visualisations of the piece of land and build in real time.

Benefits of a 3D Laser Scanning Survey

3D laser scanning in construction offers numerous outstanding benefits, including:

- Secure accurate point clouds to create 2D CAD drawings and 3D BIM models

- Reduce manual labour

- Provide real time data

- Reduce length of survey

- Eliminate the risk of human error that can be costly in any build project

Are There Any Limitations?

While 3D laser scanning surveys have numerous excellent benefits that far outweigh traditional surveying methods, they do have their limitations, including:

- It can be expensive

- Bad weather can negatively impact the function of the scanner

- The data doesn't have colour

- It requires proficient analysis to fully understand

What to Expect with a 3D Laser Scanning Survey

Your surveyor will probably have the latest 3D scanning technology that is able to capture a million, if not more, data points per second, providing you with high level of functionality and detail. The surveyor will spend some time on site, using the scanner, and then return to the office, using specialist software to create the scans in your chosen format, that can be a 2D CAD drawing, 3D CAD drawing, rectified image, or a point cloud.

The Future of 3D Laser Scanning in Surveys and Construction

With technology constantly advancing, the future of 3D laser scanning surveys is looking promising with potential enhancements including portability, integration, and affordability. Artificial Intelligence and augmented reality could both play a pivotal role in 3D laser scanning surveys in the future, opening up new opportunities for applications.