What is 3D Laser Scanning Used for in Construction?

posted 14th June 2024

3D laser scanning is a very powerful tool that is used to capture physical objects and environments in three dimension. It is popular in the construction industry, used for accuracy, safety, and efficiency. 3D laser scanning is used for quality control, documentation, safety, and inspections.

3D laser scanning is effective in helping reduce errors, saving valuable time and money, while reducing the risk of accidents on site by providing detailed and accurate documentation.

By providing accurate and detailed as-built documentation, improving quality control and inspection, and improving safety, 3D laser scanning can help to reduce errors and omissions, save time and money, and reduce the risk of accidents or injuries on construction sites. Overall, the use of 3D laser scanning in construction is increasing as the technology becomes more widely available and affordable.

3D Laser Scanning at a Glance

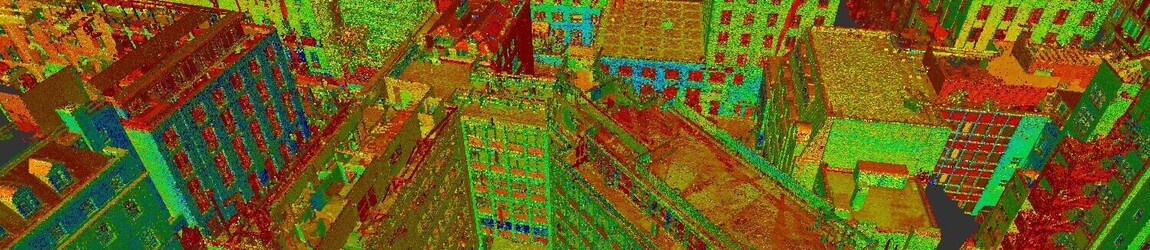

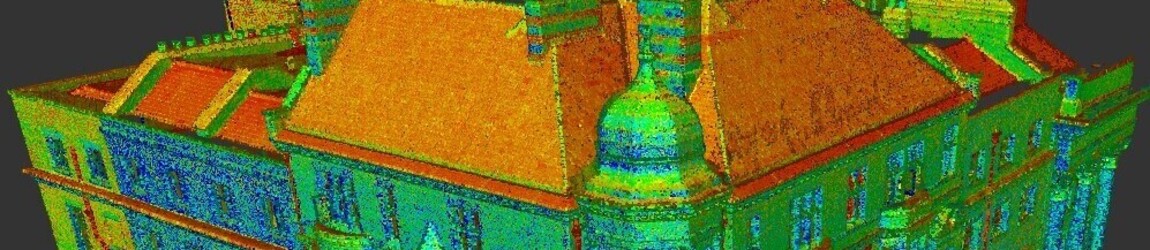

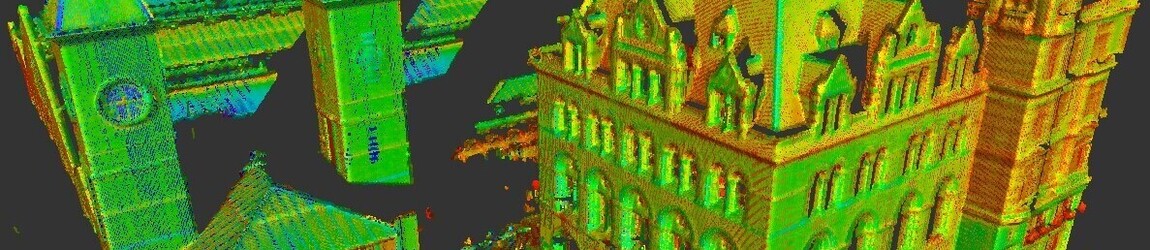

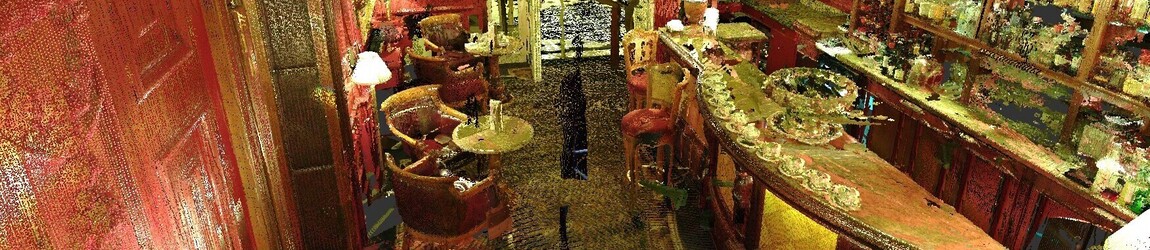

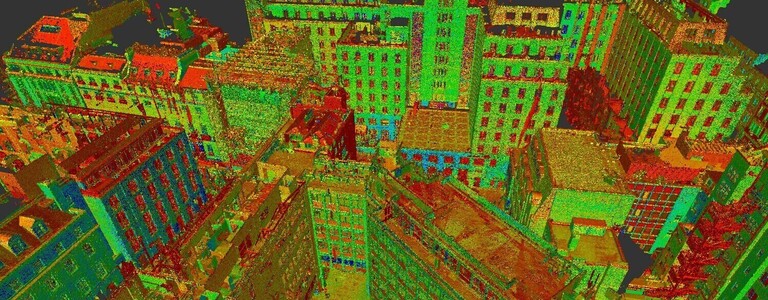

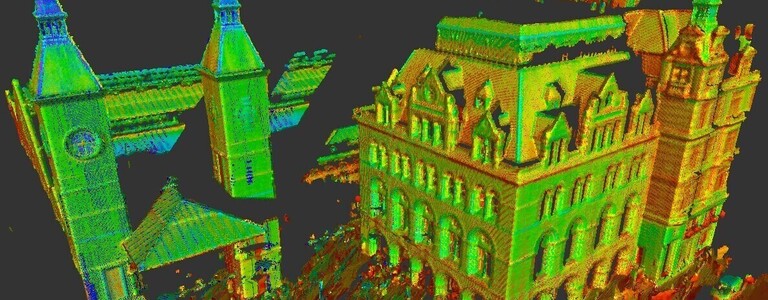

This technology uses lasers that create a digital model of an object or space. Using a laser scanner, it is able to measure surface distances. As the scanner moves around the space it captures millions of point clouds, which is then used to create a 3D and detailed representation of the space.

What Equipment is Used?

3D laser scanning uses specialist equipment that captures and processes the data, creating a digital model. The main equipment used includes:

- Laser Scanner – a device that emits laser beams, measuring the surface distance

- Specialist Software – Software is used to process the data captured by the laser scanner to create a digital model. The software analyses, edits, and manipulates the data, creating a visualisation of the space

- Tripod – used to stabilise the scanner during use, ensuring correct positioning

Benefits of Using 3D Laser Scanning in Construction

3D laser scanning is advancing, providing accurate measurements for construction. It has proven to be more effective than traditional surveying techniques.

Accurate

One of the main benefits of 3D laser scanning in construction is the high accuracy rate. It has an error rate of less than two millimetres. This ensures you secure precise measurements and data, including angles, irregular shapes, and curves. Traditional surveying methods are prone to human error and equipment malfunctions.

Efficient

3D laser scanners are able to capture vast amounts of data accurately and quickly. It is an efficient method to gather measurements and create a digital model. Traditional methods are time-consuming and labour-intensive, especially when measuring large projects.

Versatile

3D laser scanning can be used to scan a variety of surfaces and objects, including irregular surfaces, hidden objects, and complex shapes. It can can outdoor environments, including bridges and landscapes. On the other hand, traditional methods are difficult when capturing unique features, often limited to specific environments.

Contactless

This is a contactless method, meaning there is no physical contact with the space being measured, making it ideal for hard to access spaces or those that are sensitive to touch. Traditional surveying requires physical contact, that can be damaging or inconvenient.

3D laser scanning is more versatile, efficient, and accurate than traditional methods.

Traditional Methods

To fully understand how 3D laser scanning is beneficial for construction projects, you need to know understand the challenges surrounding traditional surveying methods.

There are numerous problems that arise using traditional surveying methods. This is where 3D laser scanning comes into play, improving accuracy, efficiency, and versatility when it comes to surveying your site before construction begins.

Traditional methods tend to be expensive and time consuming, especially on complex and large projects. These require specialised equipment and experienced surveyors to collect and analyse the information.

They tend to be inaccurate as traditional methods increase the risk of errors, resulting in incorrect measurements. These errors can increase the costs, when changes need to be made half way through construction.

Traditional surveying methods also had very limited scope, only providing a limited view of the site without capturing all the important data required to carry out the project.

Conclusion

3D laser scanning is used for construction projects to provide accurate measurements and information, creating a 3D visualisation of the land. It is used before construction begins, ensuring the land is suitable to build on. The measurements are used by architects, construction companies, engineers, electricians, and plumbers. 3D laser scanning provides accuracy that is difficult to ensure when using traditional surveying methods.