What are the advantages of using laser scanning for surveys?

posted 22nd August 2024

As with many industries, the surveying industry has seen numerous technology advancements recently, one of them is 3D laser scanning. Earlier laser scanners were expensive with many industries unsure if the technology was worth it or now. The newer technologies are cost-effective, proving their value in the surveying industry throughout the world.

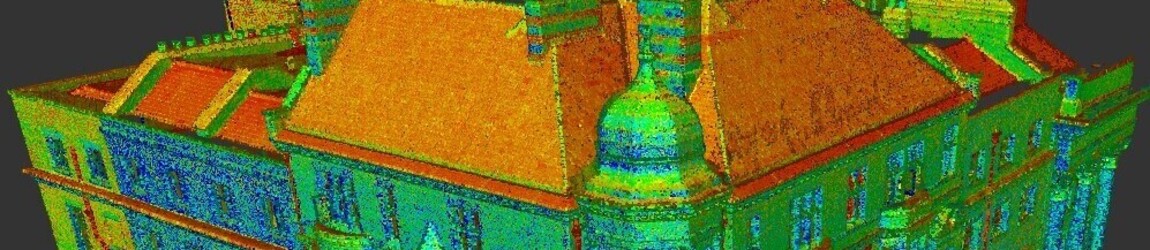

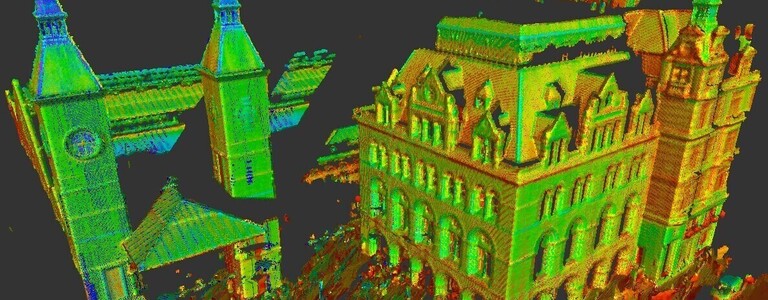

At MB Survey Solutions, we have found that 3D laser scanning has improved the precision and accuracy of surveys, providing accurate data points that we can upload using specialist software, enabling us to produce high quality 2D drawings and 3D models.

3D Laser Scanning Benefits in the Surveying Industry

3D laser scanning provides the surveying industry with a range of excellent benefits, including:

Reducing Surveying Times

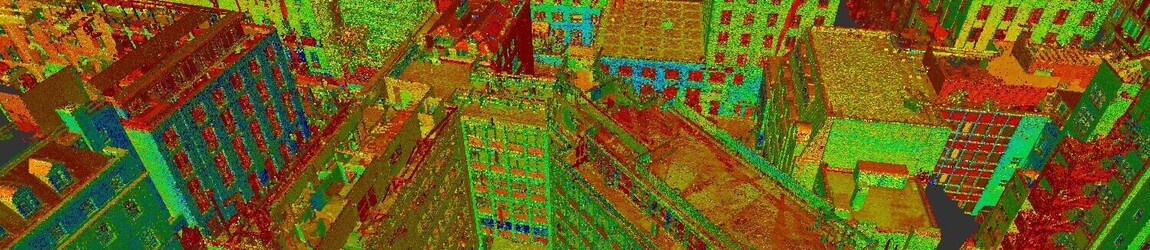

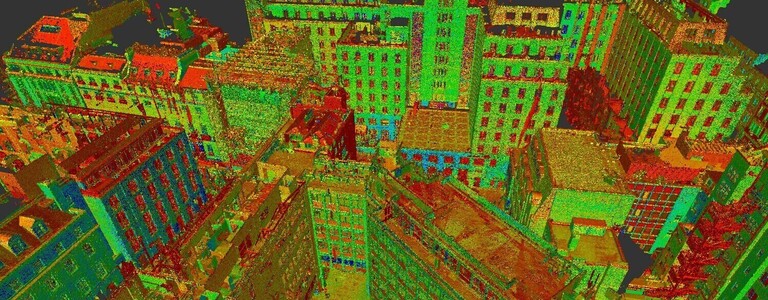

Laser scanners are able to collect data on existing structures in a short time, when compared to traditional surveying methods. It requires fewer surveyors on site. Surveys that would have taken days to complete, can now be done in one day, saving valuable time. 3D laser scanners are able to capture thousands of data points per second and then they are uploaded using specialised software, creating as-built models that you can share with your design team.

Improves Collaboration

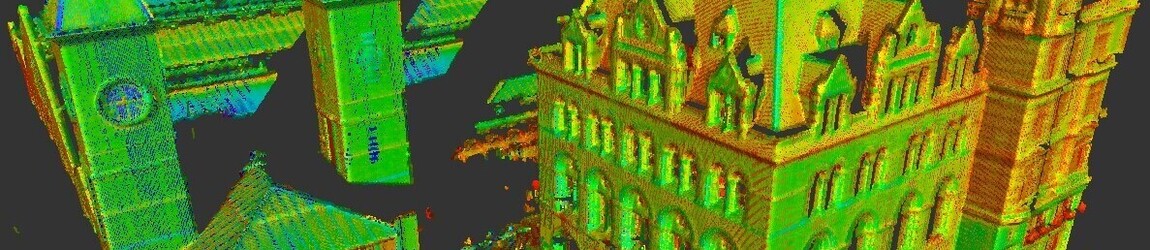

All parties involved in the design and construction of the project can share the 3D virtual models of the existing structure electronically. This improves the design process. It allows for a more efficient survey, that is precise and accurate. The file format we send your drawings or models in can be downloaded on any computer quickly and effectively, providing a visual document that aids in the design and building process.

Identifies Coordination Issues

Laser scans are high resolution, which enables designers to create 3D models, showing any coordination issues that could be time consuming and expensive. The last thing you want is to arrange an extension on your home, only to find problems later on, that delays the project. Whether it's electrical, plumbing, or duct work elements that existing, or if you need to determine if there is enough space for plumbing and electrical, our precise models, answer all your questions before building work begins.

Integrates with Specialist Software

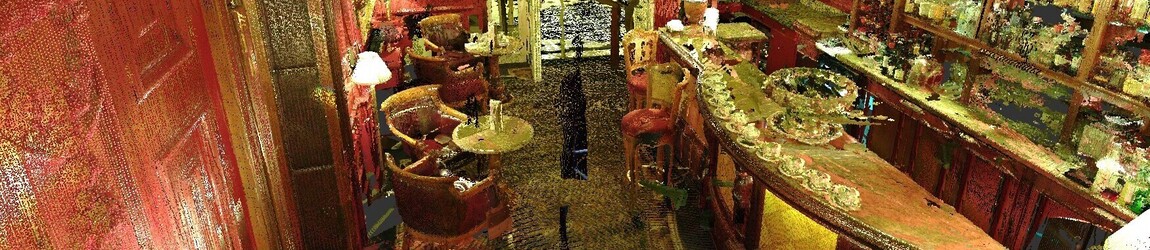

As previously mentioned, we use specialist software to upload the data points from the laser scanner. This enables us to make enhancements, overlaying multiple point clouds, to create a 3D model. Our surveyors then use the software to stitch the data points together and clean up any digital noise that the scanner may have captured in the surveying process, providing you with accurate drawings that you can trust.

Not Many Limitations

Laser scanning technology is evolving and improving and we find that there are very few limitations when it comes to using this technology. We have found that wet conditions can compromise accuracy, as can glass structures, due to the reflection. Thee challenges are avoided through our strategical planning. We scan each space at a time, ensuring sunlight and traffic are reduced. We also clean up the scans manually, editing out points that don't relate to your structure.

Conclusion

3D laser scanning has become a vital piece of equipment here at MB Survey Solutions. These scanners have improved dramatically in terms of design, accuracy, and efficiency. We use this technology to not only provide you with an accurate survey, but to improve efficiency, saving you money on your chosen survey, thanks to the speed we are able to carry out the on-site part of the survey.