How do you ensure the accuracy of your as-built surveys?

posted 10th September 2024

One of the most important factors in any building project, is keeping your project on track. Human error, inefficiencies, and lack of organisation, can quickly cause your project to fall behind.

As-built surveys are valuable tools for any construction project. Though mistakes can be expensive, such as relying n an inaccurate survey. This can make it very difficult to get back on track.

As-built surveys are essential in ensuring your building project goes ahead accurately and safely. The smallest error can cause lengthy delays. The good news today, is thanks to advancements in technology, as-built surveys offer outstanding accuracy, providing you with results you can trust.

What Are As-Built Surveys?

As-built surveys are the blueprint of your project. It details the project as it exists, once changes have been made. It is an in-depth record of the building as it was built, including utility location, materials, measurements, and more.

These surveys provide a visual record of your project once changes to the original plan have been made. This is essential for record keeping, ensuring future maintenance or renovations are made with as much information as possible.

Accuracy Verification

As-built surveys are carried out using advanced surveying equipment, including laser scanners. This means the measurements are accurate, unlike those taken by hand. They are carried out once the project has been completed, or during the project. This ensures the measurements are accurate and verified.

Reduced Human Error with Laser Scanning

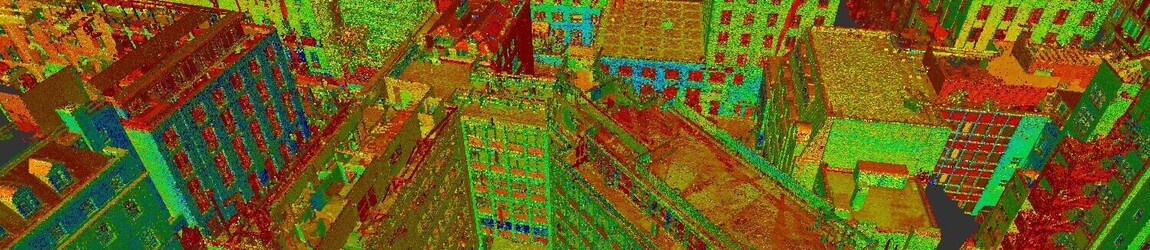

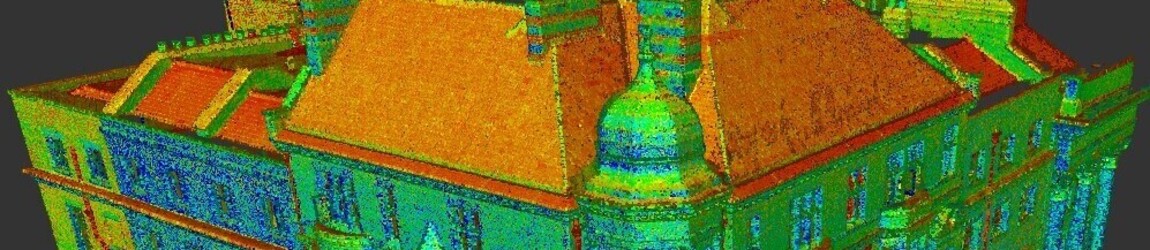

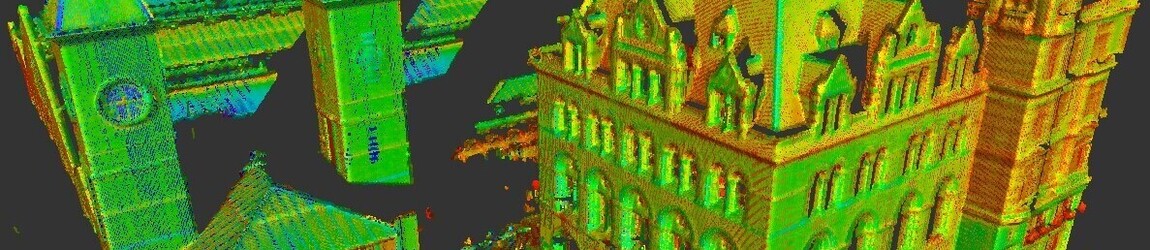

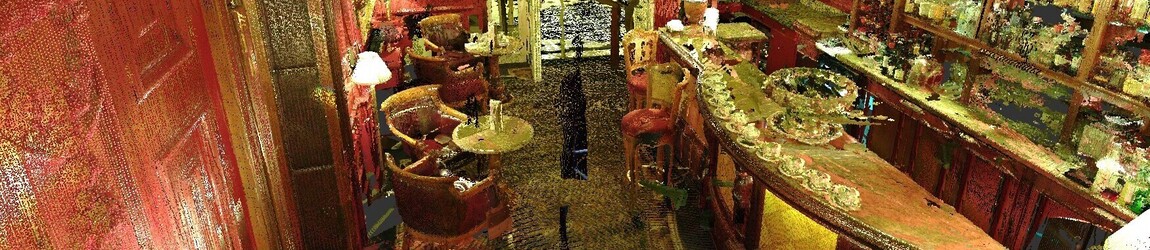

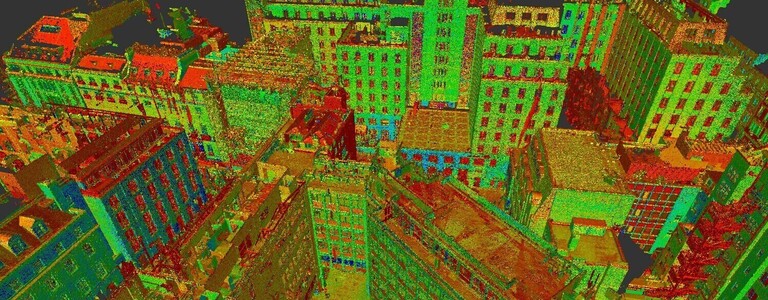

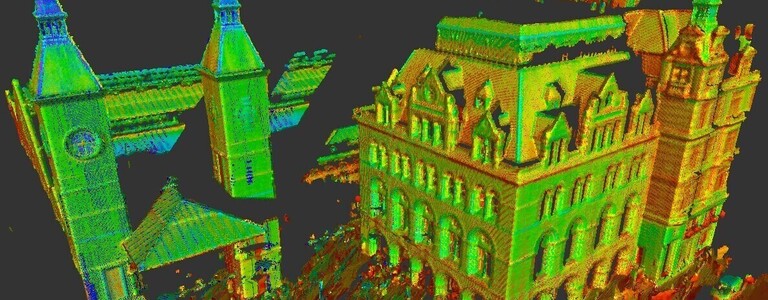

One of the many ways in which new technology is helping improve project accuracy is 3D laser scanning. At MB Survey Solutions, we rely on laser scanning to gather the information that we need This enables us to create 2D drawings and 3D models, offering the necessary details to complete the work. The major benefit of 3D laser scanning is that human error is eliminated.

3D laser scanning, also known as LIDAR data collection, works by sending a laser beam into the area being surveyed. The scanner records a point when the laser hits a surface. This results in a point cloud, that comprises of millions of survey points.

Quality Control Checks

We implement quality control measures throughout our surveying process, detecting any errors early this involves verifying benchmarks, conducting redundant surveys, and cross-checking measurements.

Standards and Regulations

In order to ensure the accuracy of our as-built surveys, we follow the regulations and standards that apply to your project. Based on location, we may need to comply with different specifications or guidelines to ensure accuracy.

Pre-Planning

All our surveys are pre-planned, this is the basic fieldwork, involving the planning and documentation of your survey. This helps us save time, resources, and avoid mistakes. The pre-planning stage involves defining the objectives and specifications of the survey.

Data is Checked and Verified

All data is checked and verified to ensure accuracy. This involves performing quality control and quality assurance, from cross checking to error analysis and making necessary adjustments. The data is checked to identify discrepancies.

Backing Up Data

All the data we collect is stored and backed up securely. This involves using reliable data formats, such as CAD, that is easily accessed, transferred, and shared. We backup our data on a regular basis, using different media and locations, reducing the risk of data loss.